ASSEMBLY

PCB Assembly Solutions: SMT, THT, and Mixed Technology Built to IPC Standards

Comprehensive PCB Assembly Capabilities

AMT provides Surface Mount Technology (SMT), Through-Hole Technology (THT), and Mixed Technology PCB assembly. Unless otherwise specified, all assemblies are built following IPC Standards Class 2.

SMT (Surface Mount Technology):

SMT is ideal for compact, lightweight PCBs manufactured in high-volume runs. It is also well-suited for complex circuits requiring high component density.

THT (Through-Hole Technology):

THT is preferred for prototyping, low-volume production, and components that need strong mechanical connections. It is commonly used for connectors and larger components.

Feature

SMT

THT

Component Placement

Mounted directly on PCB surface

Inserted into pre-drilled holes

Component Size

Smaller, lighter components

Larger components with leads

Assembly Process

Solder paste, pick-and-place, reflow soldering

Manual/automated insertion, wave soldering

Production Speed

Faster (high automation)

Slower (more steps)

Cost

Higher setup, lower per-unit cost at volume

Lower setup, higher per-unit for small runs

Mechanical Strength

Less robust under mechanical stress

Stronger bonds for heavy components

Design Flexibility

Enabled high density, miniaturization

Limited by hole size and spacing

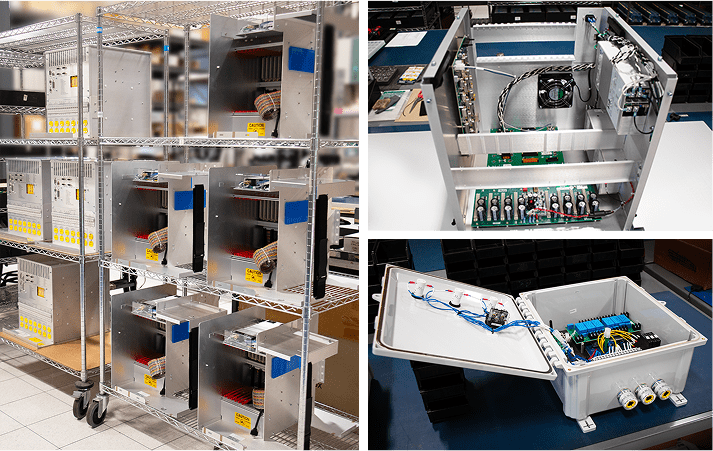

Key Features of Our Box Builds & Electronic Chassis Assemblies

- Combined Electrical & Mechanical

- Soldering, Crimping & Wiring by Using Hand Tools & Automation

- Thorough Testing

- Found in Control Panels, Cable & Harness, Power Supply, Transformer, and Sensor Assemblies

The AMT Difference

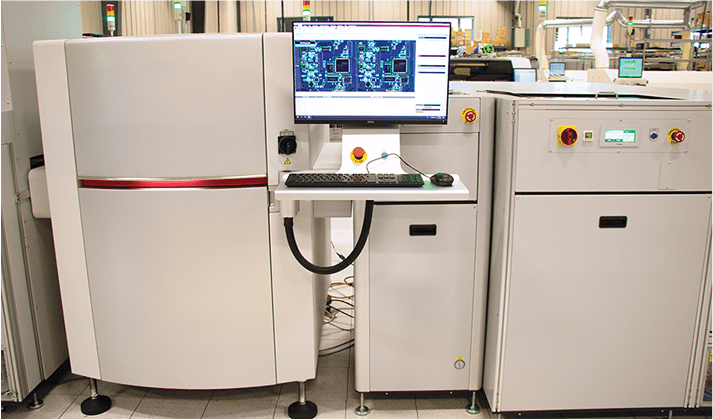

Our SMT lines support ultra-fine pitch, BGA, and micro-BGA components, as well as passive components down to 01005. Every SMT assembly undergoes 100% automated optical inspection, with optional X-ray inspection for added assurance.